Top Features to Search For in the Best Welding Shirts for Security

Top Features to Search For in the Best Welding Shirts for Security

Blog Article

A Comprehensive Overview to Selecting the Right Welding Shirts for Ideal Performance and Protection in Hazardous Work Settings

Picking the appropriate welding shirt is not merely an issue of convenience; it is an important decision that impacts both performance and security in hazardous environments. What details qualities should one prioritize to ensure optimal protection and performance in the field?

Importance of Welding Shirts

Welding t shirts play a critical function in the safety and efficiency of welders, with the ideal garment considerably impacting both defense and comfort. In the welding career, employees are routinely revealed to intense warmth, stimulates, and hazardous products, making appropriate apparel vital to reduce threats. A properly designed welding shirt can serve as an obstacle against thermal burns and various other injuries, thus guarding the welder's skin from damaging components.

Furthermore, the textile and fit of welding t-shirts straight influence a welder's capability to perform tasks effectively. Loose or badly suitable shirts can grab on tools or obstruct motions, bring about potential mishaps. Conversely, t-shirts that are also tight may restrict mobility, enhancing exhaustion and reducing overall performance.

Along with safety worries, convenience remains critical. A welding t shirt that allows for breathability while providing adequate coverage can improve focus and efficiency. Therefore, selecting high-quality welding t-shirts is not simply an issue of choice; it is an essential element of a welder's toolkit, making certain both safety and security and optimum efficiency in tough working problems (Best Welding Shirts).

Trick Functions to Take Into Consideration

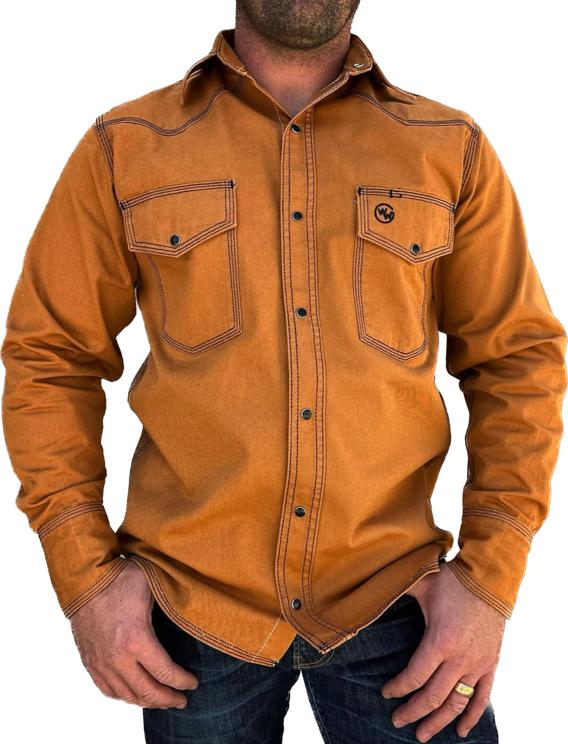

When choosing a welding tee shirt, a number of essential attributes must be focused on to guarantee both security and comfort. Appropriate fit is vital; a t-shirt that is too loosened might snag on equipment, while one that is also limited can restrict movement. Seek tee shirts with strengthened seams and sturdy sewing to enhance long life, particularly in high-stress areas.

Following, think about the design components, such as collar design and sleeve length. A high collar can provide extra neck protection, while lengthy sleeves protect the arms from sparks and warmth - Best Welding Shirts. Flexible cuffs can help secure the sleeves, stopping them from rolling up during job

Ventilation is an additional important aspect. Shirts with breathable textiles or mesh panels promote airflow, which can be valuable in hot settings. Furthermore, the weight of the textile matters; larger materials generally use better defense but might hinder convenience.

Last but not least, assess security functions such as flame resistance and anti-static residential or commercial properties. These attributes are vital for decreasing fire dangers and making sure conformity with safety and security policies. Prioritizing these crucial functions will certainly bring about a welding t shirt that enhances performance while securing the wearer.

Finest Products for Defense

Cotton is extensively utilized as a result of its breathability and convenience; nevertheless, it needs to be dealt with to improve its flame-resistant properties. Heavyweight cotton or combined products can supply an equilibrium between comfort and security. Jeans, known for its resilience, gives an extra layer of protection while keeping flexibility for convenience of movement.

Sizing and Fit Standards

Selecting the suitable size and suitable for welding t shirts is as important as the materials from which they are made. An visit the site uncomfortable t shirt can impede mobility, increase exhaustion, and present safety dangers throughout welding operations. To ensure ideal performance, it is necessary to refer to the producer's sizing chart, which usually correlates dimensions with details sizes.

When analyzing fit, think about both the body measurements and the meant usage of the t shirt. A welding tee shirt should enable a complete series of motion-- particularly in the arms and shoulders-- without being exceedingly loose, which can catch on equipment or expose skin to hazards. It is recommended to go with t-shirts that feature a relaxed fit, as they provide convenience while keeping safety and security criteria.

Furthermore, pay interest to the t-shirt's length; it should cover the upper body adequately to avoid triggers or liquified metal from entering. Sleeves need to be long sufficient to make sure coverage while functioning, preferably go to the website ending at the wrist or simply past. Finally, consider the possibility for layering; if the tee shirt will be put on over various other protective equipment, make sure there is enough area for extra garments without compromising safety and security.

Upkeep and Care Tips

Correct maintenance and treatment of welding shirts is critical to extending their life-span and making sure ongoing security and performance. To preserve the integrity of these specialized garments, it is necessary to follow certain care guidelines. Constantly check the maker's tag for washing guidelines, as different materials might have differing requirements.

When washing welding t shirts, use a moderate cleaning agent and refrain from using bleach or material conditioners, as these can compromise the protective high qualities of the textile. It is recommended to clean shirts individually from various other apparel to avoid contamination from lint or fibers that might stir up. In addition, consider using chilly water to maintain the textile's toughness.

After washing, topple dry on reduced warmth or air completely dry, as heats can damage the material and influence its safety residential properties. Routinely examine the tee shirts for indicators of wear, such as fraying joints or openings, and change them as needed to preserve security requirements.

Verdict

In final thought, selecting the home appropriate welding tee shirt substantially contributes to safety and security and performance in hazardous job atmospheres. Inevitably, an appropriate welding t-shirt offers as a crucial component in advertising both security and efficiency in welding procedures.

Report this page